Scaling Up: A Practical Guide to Managing Large-Scale Marble Table Production

Securing a reliable marble table supplier for a single, custom piece is one challenge. Managing the production of dozens, or even hundreds, of tables for a hotel renovation, a chain of restaurants, or a new corporate headquarters is an entirely different ballgame. Scaling up production introduces complexities in material sourcing, quality consistency, logistics, and timeline management that can make or break a project. This how-to guide, drawing from the extensive experience of suppliers like SONGJIA, provides a roadmap for buyers, project managers, and designers to navigate the scaling process successfully.

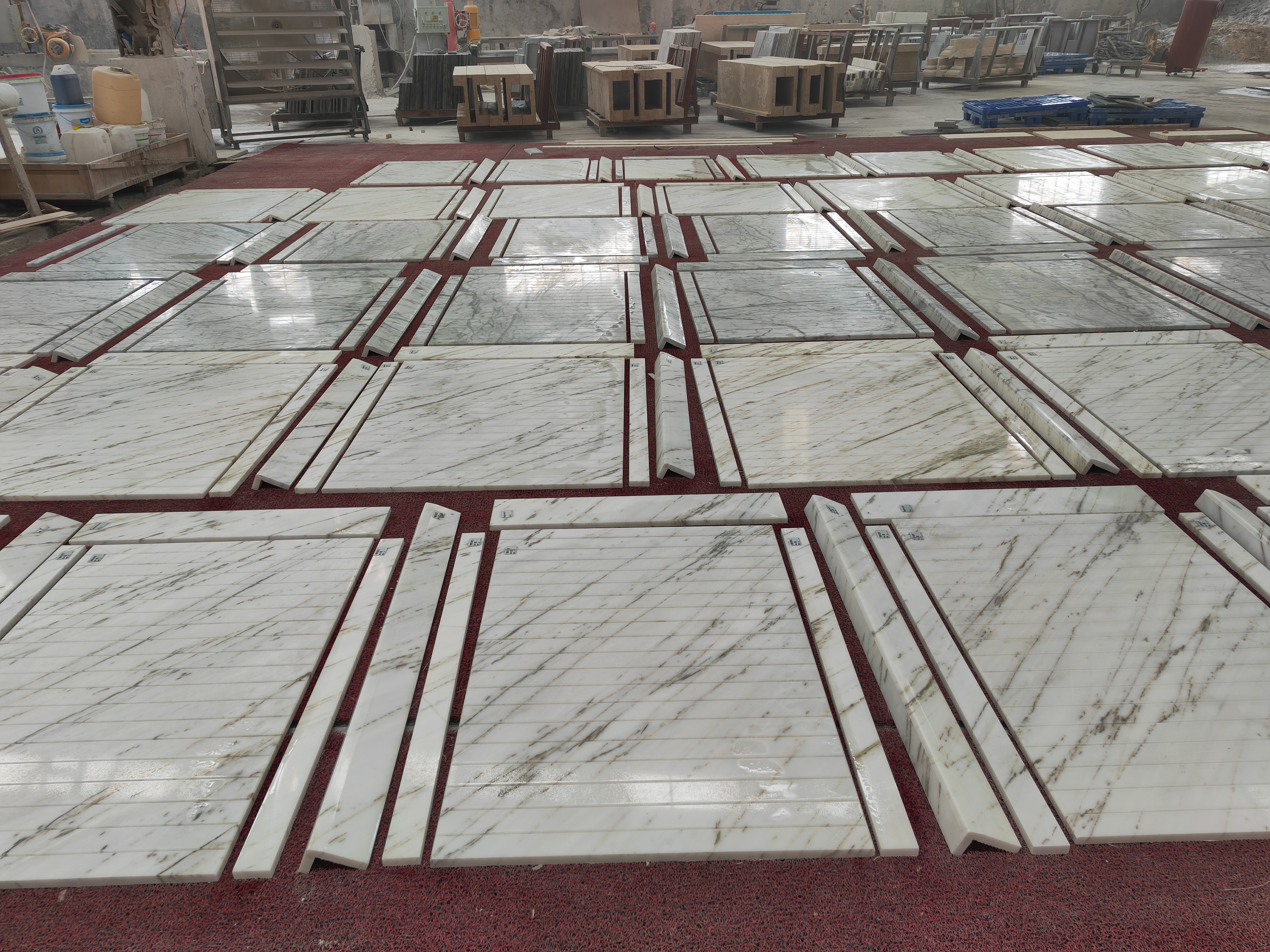

Production Scale Insight: A view inside a partner factory's grand cutting workshop, showcasing the machinery and space required for handling large-volume slab processing for commercial projects.

Phase 1: Pre-Production Planning & Feasibility

Before issuing a purchase order, thorough planning is non-negotiable. This phase sets the foundation for everything that follows.

- Define Exact Requirements: Go beyond "50 marble tables." Specify for each batch: Are they for a Hotel Banquet Hall (requiring uniformity and grandeur), a Restaurant Commercial setting (needing durability), or an Office Reception area (emphasizing brand image)? Detail dimensions, thickness, edge profiles, and finishes. For a Villa Custom Marble Table Supplier, each piece might be unique, requiring a different project management approach than a batch of identical Café Leisure Marble Tables.

- Material Sourcing & Block Reservation: Natural stone is not a homogeneous material. A reliable marble table supplier must secure enough raw material from the same quarry vein to ensure color and veining consistency across all pieces. For large orders, this often means physically reserving blocks at the quarry. Suppliers like SONGJIA, with their deep network, excel at this critical step. Inquire about their process for block selection and reservation.

- Prototype & Approval: Never skip the prototype. Produce one or two finished tables for approval. This tests the design, craftsmanship, and material appearance under real lighting conditions. It's the final check before committing to full-scale production.

- Shop Drawing Finalization: Professional suppliers will provide detailed shop drawings for each table type. These are technical blueprints for the factory, not just concept sketches. SONGJIA's technical team specializes in transforming client ideas into accurate, producible drawings, which is crucial for Custom-Size Marble Table and Large-Size Marble Table projects to avoid costly errors.

Phase 2: Production Management & Quality Control

This is where your supplier's expertise and systems are put to the test. Transparency and communication are key.

Critical Checkpoints During Production:

- Slab Layout & Matching: Once slabs are cut, skilled workers "match" them—arranging adjacent slabs to create a harmonious flow of veining across multiple table tops. This is an art, especially for prominent pieces in a Hotel Banquet Hall.

- Fabrication Consistency: Using CNC machines and skilled hand-finishing ensures every table leg, apron, and top is identical for batch orders. For a Durable Commercial Marble Table Supplier, structural integrity during fabrication (like proper reinforcement for thin tops) is paramount.

- In-Process Quality Inspection (IPQC): A professional supplier conducts inspections at each stage: after cutting, after polishing, after assembly. This catches defects early, saving time and material. Ask your supplier about their IPQC protocol.

Companies like Xiamen Songjia Trading Co., Ltd. leverage their role as a project manager across a network of specialized workshops. They don't just place an order with a single factory; they coordinate different specialists—one for cutting, another for intricate carving, another for metal bases—ensuring each step is handled by experts. This model provides flexibility and scale that a single factory may struggle with.

Phase 3: Logistics, Packaging & Documentation

Getting hundreds of heavy, fragile tables safely to their destination is a logistical feat.

- Customized Packaging: Each marble table, especially a Large-Size one, needs a custom-built wooden crate with foam padding and proper blocking to prevent movement. Foldable Marble Table designs can simplify packaging but require careful attention to hinge protection.

- Container Optimization: An experienced supplier will maximize container space to reduce shipping costs. They calculate how to nest tables, bases, and accessories efficiently. For a full container load (FCL) order, they handle all stuffing arrangements.

- Documentation: Ensure all commercial invoices, packing lists, and certificates of origin are accurate. Reputable suppliers like SONGJIA can also provide relevant mill test reports or certificates, such as their SGS VERIFICATION OF CONFORMITY certificates (e.g., for G654, G684 granite), which attest to material quality and consistency—a vital trust factor for large commercial clients.

Why Partnering with an Integrated Supplier Like SONGJIA Makes Scaling Easier

For project-based buyers, working with a versatile partner like SONGJIA (www.songjiaglobal.com) mitigates many scaling risks. Their model is built for control and reliability:

- Design-to-Production Bridge: They translate vague concepts into manufacturable plans, crucial for complex Villa Custom or unique Office Reception pieces.

- Network, Not Just a Factory: They tap into a mature manufacturing network, allowing them to scale capacity up or down based on your project needs without being limited by one factory's schedule.

- Single Point of Contact: You manage the entire process—design, stone selection, production across multiple workshops, QC, and shipping—through one professional team at SONGJIA. Contact them at info@songjiaglobal.com or on WhatsApp: +86 15359293102 to discuss your project scale.

- Focus on "Easy-to-Clean" & Durability: Their experience supplying the commercial sector means they understand the need for practical finishes and robust construction that defines a true Easy-to-Clean Marble Table Supplier and Durable Commercial Marble Table Supplier.

Conclusion: Scaling with Confidence

Scaling marble table production is a detailed process of coordinated steps, from quarry to installation site. Success hinges on choosing a partner with the technical expertise, supply chain management skills, and quality systems to handle volume without compromising on the individual quality of each piece. By following this phased guide—meticulous planning, insisting on transparent production management, and ensuring robust logistics—you can confidently undertake large commercial, hospitality, or residential projects, turning the challenge of scale into a showcase of seamless execution and enduring beauty.

For architects, procurement managers, and business owners looking for a marble table supplier capable of handling both bespoke one-offs and large-scale batch production, the integrated, controlled approach offered by specialists like SONGJIA provides a reliable pathway to project success.